Supporting Construction & Plant Upgrades

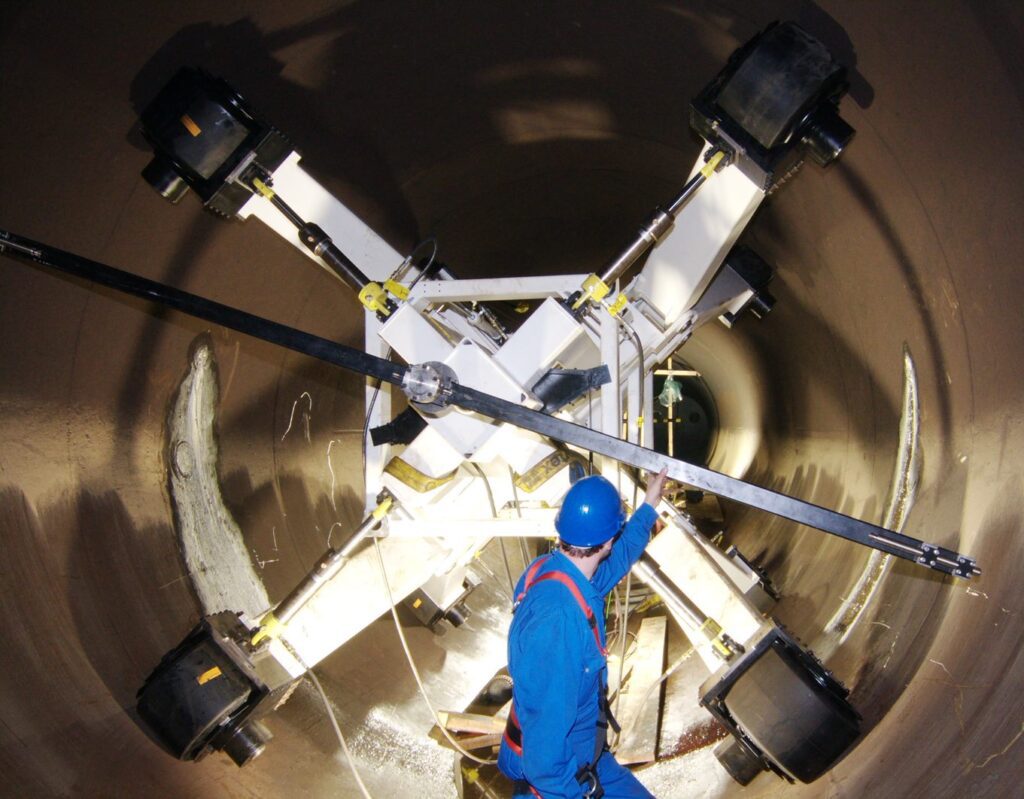

Industrial Cleaning & Surface Preparation Services

Surface Preparation Services Including Concrete Repair, Hydro Demolition, Aqua Jetting, Coating and More.

Prepare surfaces for construction, refurbish and repair concrete, all while lowering overall project costs and improving safety. Services include:

Water Intrusion Control & Concrete Repair

Proven approach to repair with proprietary epoxies, micro-cements, and high-performance urethane grouts engineered to mitigate the effects of problematic water intrusion conditions.

Surface Preparation

Water jetting and abrasive blast techniques with specialized equipment to remove product build-up, dirt, oil, corrosion scale, and failed coatings down to the substrate.

Coating Application & Removal

Apply new coatings or recommended coating systems for steel and concrete surfaces. Can be combined with surface preparation services for excellent results.

Hydrodemolition of Concrete & Concrete Preparation

Remove deteriorated concrete safely and cost-effectively while leaving sound concrete with a rough profile, perfect for bonding the newly poured overlay.

Consulting & Reporting

Faced with a particularly unique, challenging and complex problem? We can design and implement custom solutions, technical reports, or act as a consultant.

How Can We Help?

Get A Quote for Turnaround Services, Additional Information, or Technical Help by Reaching Out:

Get to Know How We Operate: Recent Case Studies

‘Uncleanable’ Heat Exchanger Bundle Saved by EMBC Tech

A large heat exchanger bundle at an asphalt plant had been idle for four months with hardened residue that other contractors could not remove with hydroblasting. In six hours, Blue Wolf’s EMBC bundle cleaning technology fully cleaned and tested the unit, returning the heat exchanger to maximum efficiency.

Online Liquid-Lancing Technology Prevents $18 Million Shutdown

Hydrate ice on a plate heat exchanger was creating unwanted resistance and a pressure drop, impacting ethylene production. Blue Wolf was able to melt the ice under live conditions – avoiding shutdown – using our proprietary Liquid-Injection-Lancer (LNL). This saved the facility an estimated $18 million in avoided shutdown.