Proprietary Technologies

Blue Wolf Performance Solutions has pioneered automation in industrial cleaning utilizing a suite of proprietary and/or patented technologies that have been developed in-house. Blue Wolf’s industrial cleaning solutions ensure effective cleaning, safer operations, and faster turnarounds. Learn more about our robotic aquamiller, hydrolazing, and hydromilling technologies below, reach out for a quote, or contact us directly at 281-337-0900 to discuss how we can improve the performance of your critical assets. Our industry leading “hands-off” cleaning technologies deliver:

- Complex piping system cleaning navigating multiple 90-degree pipe elbows in pipes from 1.5” to 80” diameter

- Extremely long reach from entry point minimizes the number of pipe entry points (up to 2,500ft has been reached in piping less than 36 inches; 8,000 feet in piping greater than 36 inches)

- Effective removal and extraction of extremely hard scale that conventional cleaning & hydrolazing cannot remove or transport out of the pipe

- “Hands-off” cleaning of heat exchanger and reactor tubes to IRIS inspection standards without the use of “Ultra High Pressure” (UHP) water jets and without the associated risk of tube erosion

- Cost savings & complete elimination of downtime with our unique ability to clean towers/piping and vessels online while in pressurized “live” service

- Highest safety levels using a wide range of proprietary “hands-off” aquamiller cleaning systems that eliminate the need for man-entry into confined spaces, tanks, vessels, or reactors

- Significant reduction in cleaning time through the use of customized cleaning systems that simultaneously utilize 750-2,500 HP jet cleaning and 500 HP suction HVAC

| Technologies | Description | Benefits |

|---|---|---|

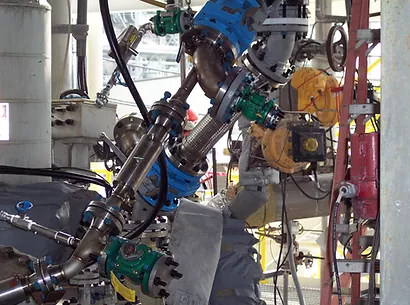

Hands-Free Aqua Milling | Removes and transports extremely hard scale “hands-off” and succeeds where other hose rotating cleaning systems fail or require significantly longer cleaning times. | * Safer – cleaning parameters are controlled remotely * 5-10 times longer reach from entry point vs. traditional methods * Minimal downtime and interruption to plant operations * Cleaning “live” piping systems using sealed entry option * Complete surface coverage using remote hydraulic feeding system |

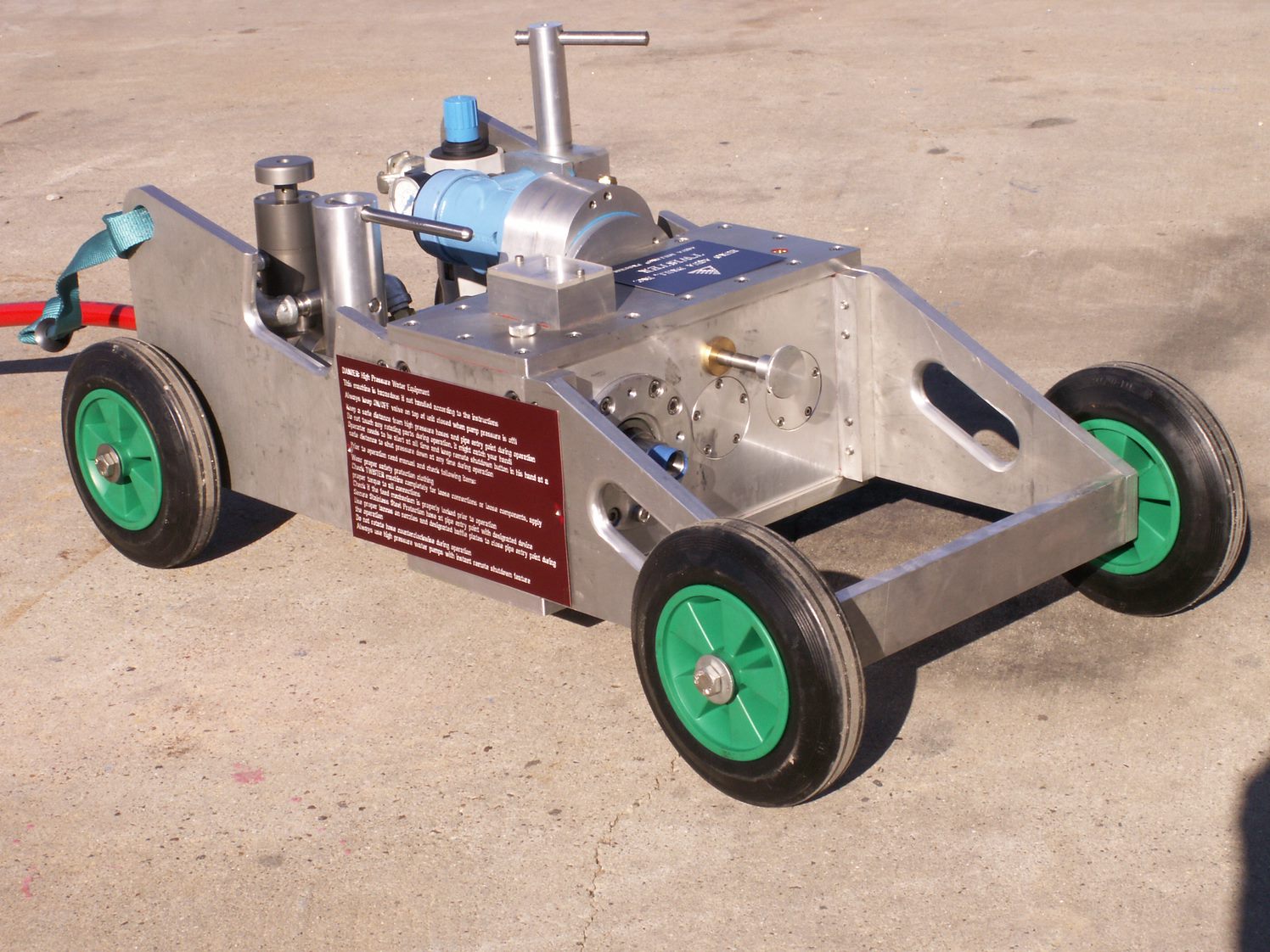

Robotic Aqua Rover | Robotic hydromilling high-pressure cleaning system that removes coatings, corrosion, concrete liners and hard scale or mill-scale deposits from large-diameter piping (3 ft to 17 ft diameter) | * Safer – self-propelled robotic system externally controlled * Longer reach, depending on size, up to 3+ miles * Faster & more effective – precision, robotic cleaning * Flexible – eight custom designed versions that are adaptable to complex piping systems |

High Powered Aqua Lancer | High pressure aquamiller jet cleaning of fully or partially plugged tubes from extremely small to large tube diameters (3/8 in to 4 in diameter). Frequently used to meet IRIS inspection cleanliness criteria | * Safer – robotic system controlled by remote operators * Faster – high horsepower simultaneous cleaning of multiple tubes * More effective – works efficiently where 40K UHP cleaning is not successful |

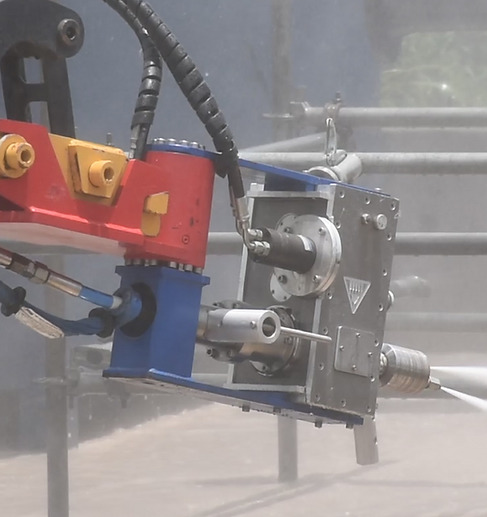

High Powered Aqua Ex | Remotely controlled high powered hydromilling cleaning jets permit trained operators to clean complex geometrical surfaces utilizing a variety of externally driven rotating water jets. The operator cabin is air conditioned, and the unit commonly cleans the shell side of heat exchangers or extruders | * The most flexible cleaning system on the market – for challenging surfaces & geometries. Fully articulated cleaning nozzle for cleaning in any direction. * More effective – – designed to utilize flow and pressure from 400-800kW (600-1200HP) high pressure water pumps * Safer – operator in fully enclosed A/C cabin |

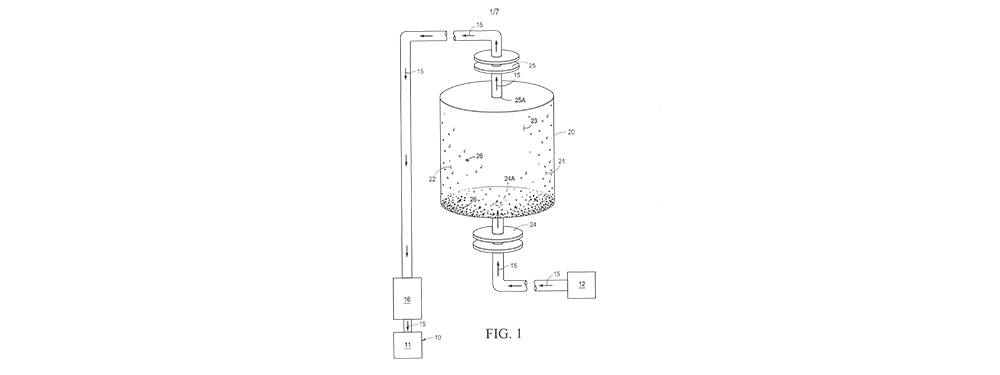

Enclosed Mobile Bundle Cleaner (EMBC) | This unit uses high volume flow (up to 1,500 gpm) of cleaning agent in an enclosed machine. The solution is heated and moderately pressurized and pumped through more than 400 spray jets while the bundle is constantly rotated. The jets, coupled with the constant rotation of the bundle, provide constant contact with the cleaning agent down both sides. | * More effective cleaning – cleans all the way to the center of tight pitched bundles * No over-spray, splatter, or run-off – cleaning agent is processed through a closed kidney loop filtration system and all particulates captured and disposed * Safer – this low-pressure flow, self-contained approach is much safer than high-pressure and open vat methods * ZERO hazardous liquid waste with most coolers. When a water-based cleaning solution is required, 93% less hazardous liquid waste is produced * Superior Results – process restores heat exchangers to 92% – 98% of their new efficiency |

| Process-in-Operation (PIO) Piping & Tower Cleaning Cleaning  | PIO (Process-in-Operation)- Aqua Milling® and PJL (Petro-Jet-Lancer) Online Cleaning has routinely been utilized by Blue Wolf for years to avoid costly production shutdowns of piping, towers, tanks, or reactor vessels. Using hot-taps or small lateral entries, the cleaning equipment enters “live” equipment using a hydraulically activated “launcher” and a dual seal system. Various custom devices and aquamiller procedures are used to transport and retrieve the scale particles from “live” pressurized process units. | * Zero downtime– Piping system remains in full service during PIO-Aqua Milling® or PJL online cleaning operations. * Highly specialized seal and launcher technology allows tower or pipe entry at high pressure/high temperatures. * Zero Exposure – the remotely controlled PIO/PJL cleaning system eliminates exposure to pipe internal gases, hazardous conditions or spillage. Blue Wolf’s closed system containment is connected to the PIO equipment completely isolating the internals of towers, piping, and vessels from the environment |

360 Tank TotalScrub System | Blue Wolf’s Tank TotalScrub System sprays oil in a 360 rotation, allowing the run-down tank interior to be simultaneously “washed” with the flushing oil. This system features: * 360° rotating interior oil spray wand * Ability to coat and clean all internal surfaces during HVOF * Full wash-down capabilities | * Faster – Savings of 24-36 hours of cleaning time per vessel with concurrent HVOF & tank cleaning. * Highly Effective for Surface Cleaning – Complete cleaning of all interior tank surfaces and removal of contaminants including varnish, deposits, and sediment * Highly Effective Oil Reconditioning – Successful cleaning of oil systems to ISO recommended levels |

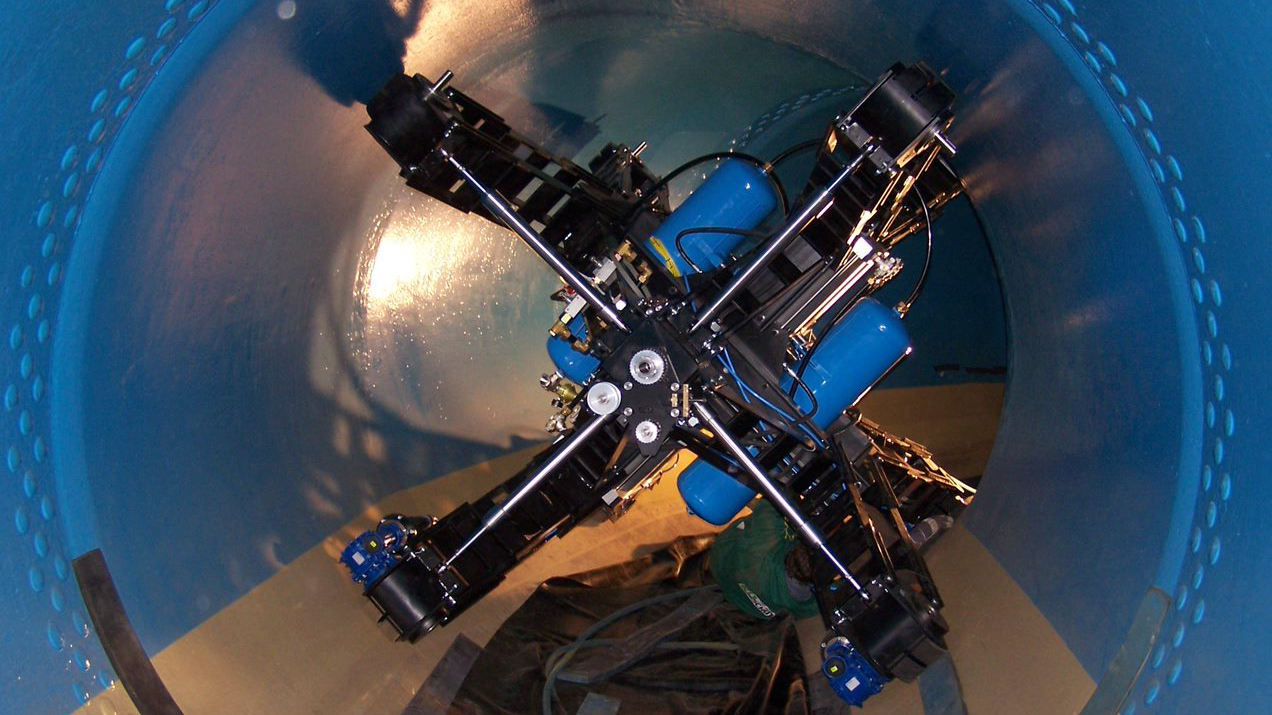

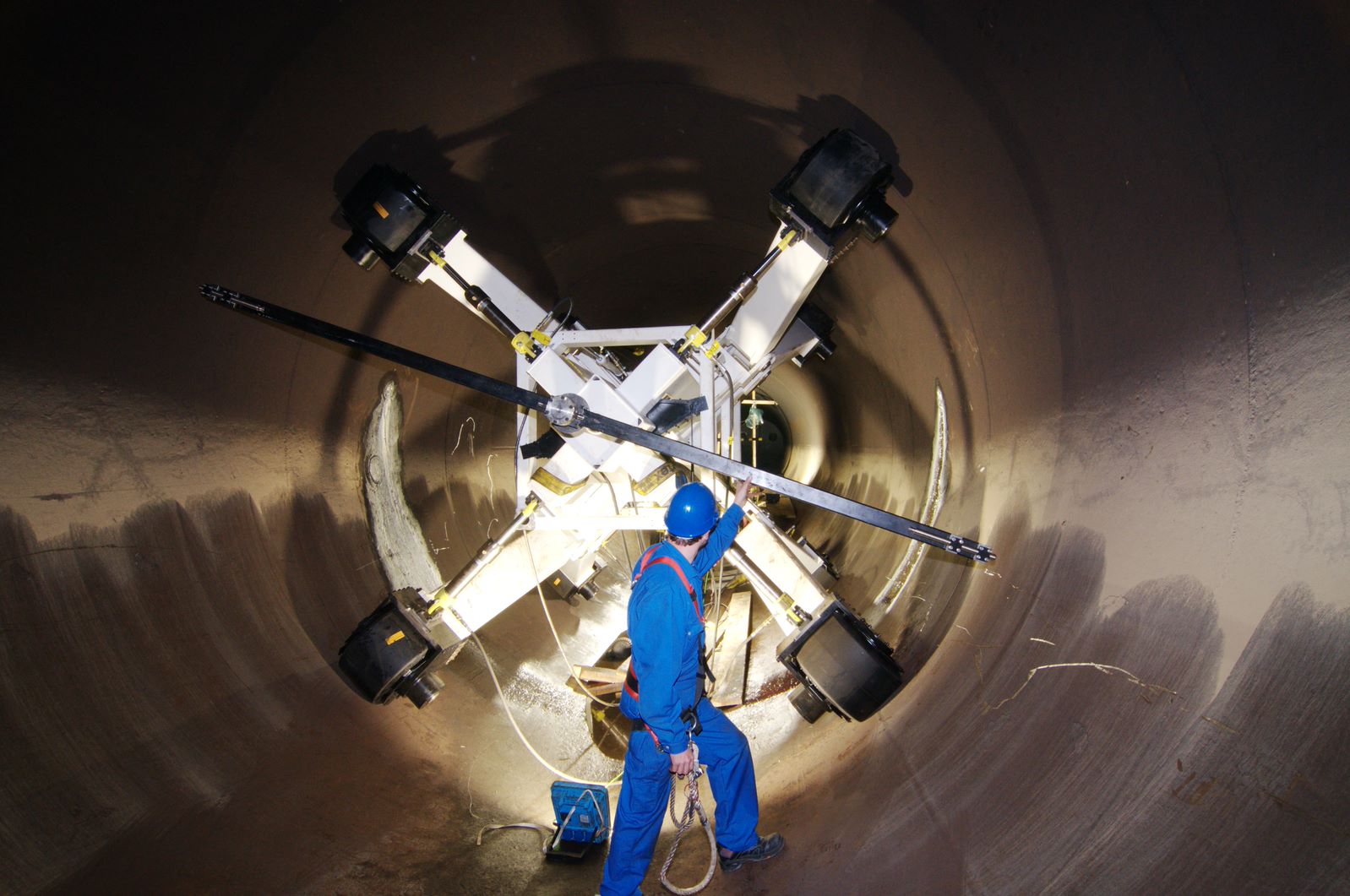

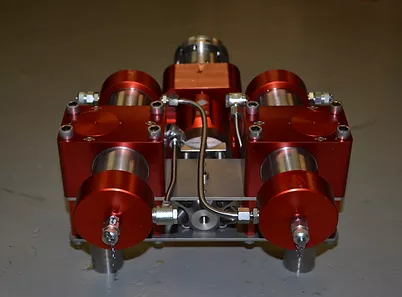

Robotic Tank Spider | Robotic hydrolazing, remote cleaning of interior vessels, tanks & reactors (3 ft to 30 ft diameter) | * More Effective – up to 2,400 HP can be utilized to power a single Blue Wolf tank cleaning head, ultimately leading to fast and un-matched cleaning results with nearly all types and volumes of scale or contamination * Safer – operated with external controller and hydraulics and without personal inside confined space during operation * Agile – Blue Wolf’s hydraulically and pneumatically driven positioning arms are used to accommodate various types of vessel entry and are often guided by remote video monitoring thus enhancing the speed of the entire operation. |

Get a Quote

Want to use one of these technologies at your site? Fill out the form below and we will get you a quote. For immediate assistance, call: 281.337.0900