Preventing and controlling varnish is a major concern in the vast majority of gas turbines. Before you can implement new controls, the first step is to give your system a fresh start by removing accumulated varnish. We’ve created this guide for you because chemical cleaning is the most common approach to removing system varnish.

Testing

First and foremost is testing to verify how much varnish is currently in your system. If your oil is already saturated with varnish, just adding chemistry to the current charge of oil can be pointless. The chemistry solubilizes the varnish deposits that have “plated” out in the system to be carried with the oil. The oil has to be able to hold these deposits.

Varnish mitigation units can be installed to remove varnish if levels are low enough, in cases where varnish levels are exceedingly high, a 50% bleed and feed or a base stock flushing fluid can be utilized.

Heat & Chemistry

Two methods are tried and true for getting rid of varnish from surfaces: heat and chemistry.

- The oil solubility of varnish depends on temperature—the hotter the oil, the more varnish dissolves in it

- The right chemicals also dissolve and disperse varnish, so it drains from the oil

- Typically, the most effective method is to combine heat and chemistry

Cleaners

The most common varnish removal method is to add a cleaner to your in-service oil and circulate it while hot. Several commercial cleaners, using solvency, detergent or dispersant properties or a combination, loosen varnish and put it in solution, or suspension, in oil. In this section, we give you an overview of some of the most popular cleaners available.

- Mobil System Cleaner – Recommended

- DuBois Step-One Cleaner

- Schaeffer Neutra purging fluid

- Summit Varnasolv

- Citgo Compkleen

- King Industries NA Lube – KR008

Cleaning Process

Add cleaner at a 5–10% concentration (per manufacturer instructions) to the oil in service and circulated at or just above operating temperature (130–160 degrees) for 24-72 hours to clean the system.

Then, drain the oil and cleaner (and removed crud)—while hot—and dispose of it. That may sound like a straightforward process, but there are some pitfalls it’s critical to avoid. We’ll cover best practices below.

Timing Your Cleaning

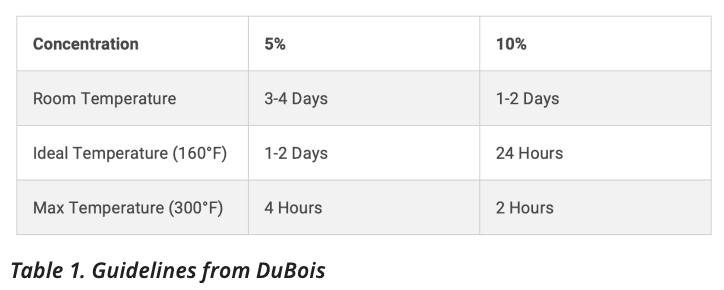

When cycling cleaner through your system, the in-service oil becomes unusable, so it’ll save you money to time your cleaning with an oil change. To get the job done right, set aside sufficient time for your cleaner to cycle through your system. As an example, these are the guidelines from DuBois:

It takes a while to remove years of caked-on varnish, and usually that time is set before a shutdown begins, so the impact on shutdown time is small. It’s also crucial to maintain temperature, as it’s most effective to dissolve varnish in hot oil. While circulating the cleaner, cycle the hydraulic servo valves (such as the IGV and FC valves) to eliminate dead or low-flow areas and clean them too.

Typically, most companies do this during the turbine cool down period. If your filter system is set up for duplex flow, oscillate it back and forth during circulation to clean both filter housings and coolers.

Water

- Cleaners severely reduce water separability, so coalesce and centrifuge separators won’t be effective during cleanings

- If you see major water ingress in a steam or hydro turbine, you might require an auxiliary vacuum dehydrator to remove water

- You can also clean the turbine while it’s not in operation

Particle Contamination

- Varnish is inherently sticky, and solid contaminants get stuck in varnish deposits

- As varnish dissolves back into oil, particles go back into circulation

- Solid contaminants that have accumulated through the years can be released into your oil in a couple days, creating a high concentration and causing damage

- To mitigate this, bring in auxiliary kidney loop filtration to help remove particulates from circulation while your system circulates

Draining Your System: Keep Your Oil Hot & Circulating

- Circulate your oil at operating temperature until you drain it

- The oil solubility of varnish varies with heat, so if your oil, cleaner and varnish cool down together, the varnish will separate and re-deposit

- Keep your temperature up, then drain the oil before it cools

Draining Low Spots

- Oil can pool in certain spots within a turbine lube oil system and not drain back to sump when circulation stops

- To remove all cleaner and dissolved varnish, complete draining is crucial

- Break open flanges and drain plugs to drain these spots and remove as much of the oil/cleaner/gunk solution as possible

Flushing

- Remove all cleaning solution from your system because any residual cleaner left in the system will hurt the performance and life of your new turbine oil

- Most high-grade turbine oils are ashless formulations and slightly acidic, so they’ll react with the calcium in some cleaners and partially deplete your new oil additive package

- Any remaining detergent will also impact the water separability of your turbine oil

Traditional Flushing

- It was common to flush the system twice to remove all system cleaner and any particulates.

- But with proper draining, you can rinse out cleaner with just one flush.

- In fact, you can often rinse two turbines with one flush oil! The key? Properly drain your systems both before and after the flush. You’ll save plenty of money by doing this right.

- Fill the system to the minimum operating level and circulate the oil with system pump for a 12-hour period. Cycle Hydraulics, filter housings and coolers hourly. This process has proven to remove over 99% of system cleaner

- Re-draining all the low points after the purge will increase the percentage even higher

Displacement Flushing: Not Good For Turbine

Displacement flushes are good for simple piping runs where oil is pushed once through the pipe. But they don’t work for turbines. Here’s why:

- They don’t use system pumps

- Flow rates are greatly reduced

- The hydraulic system isn’t flushed

- They don’t effectively flush particulates back to the sump

Reservoir Wipe Down

The last part of a cleaning is wiping down the walls ceiling, piping and floor of the lube oil reservoir with lint-free rags. For safety, use only confined-space entry certified personnel.

- DO USE DETERGENTS TO WIPE DOWN THE RESERVOIR

- Even a little detergent left behind will impact water separability of the final fill oil

- Sometimes, varnish will be evident in the reservoir vapor space—if varnish is present, spend extra time to wipe and scrape it off

- While inside the reservoir, have personnel collect any unusual debris that can indicate turbine equipment degradation or pending failure

Final Fill Oil

The final step is to fill your system with turbine oil, filtered through a high-efficiency filter skid going into the reservoir and kidney loop filtered in the reservoir to meet the OEM specification. This fill procedure ensures any dust or fibers left in the reservoir are removed before they get into the system.

On-line Cleaning

In recent years, innovations in varnish removal have created new alternative cleaning processes, including:

- Electrostatic

- Balanced charge agglomeration

- Depth media filtration

- Ion charge bonding (ICB)

- Electrophysical separation process technologies (ESP)

Electrostatic, BCA and depth media filtration are effective in removing insoluble varnish precursors from oil. ICB and ESP are resin technologies that target soluble varnish precursors. The concept is to remove varnish precursors from oil, freeing it to act as a cleaner, slowly stripping accumulated varnish from metal surfaces.

Most of these technologies are great for slowing or stopping new varnish deposits for forming. But they’re not as proven at removing deposited varnish.

Turbine Oil

Turbine oil specifically is stable and doesn’t make for a good, aggressive cleaner, limiting its effectiveness at stripping deposited varnish—regardless of filtration technology. In limited lab experiments, removing varnish deposits from surfaces with electrostatic filtration worked just sometimes. But often, varnish just stays put.

The success of this approach depends on several factors:

- Current oil formulation

- Natural oil solvency

- Deposited varnish composition (this can vary greatly)

- Oil temperature (hotter oil strips more varnish but releases less to your filtration unit)

- Efficacy of your filtration unit

Get Human Eyes on Every Part Before & After Cleaning

It’s tough to measure varnish and verify the efficacy of varnish removal. We can only measure insoluble varnish precursors in the oil—there’s no way to measure soluble varnish precursors and how much varnish is actually deposited through oil testing.

The only way to judge a cleanings effectiveness is with physical part inspection before and after cleaning.

Conclusion

Chemical cleaning can effectively remove accumulated varnish from an operating system but proper care must be taken to ensure more benefit than harm.

*Credit to Isoclean Solutions’ Isoclean Information Series for providing information for this guide.